Email Id: sale@adctooling.com

In the fluid transport industry, the selection of PTFE lined pipe fittings is critical. These fittings have unique properties that make them ideal for corrosive and high-temperature applications. According to a recent industry report by Global Market Insights, the demand for PTFE products is projected to grow at a CAGR of over 7% through 2026. This is largely due to their chemical resistance and durability.

Experts emphasize the importance of choosing the right fittings. Dr. Emily Carter, a polymer specialist, states, “Selecting PTFE lined pipe fittings can significantly impact system efficiency.” It highlights the necessity of understanding not just the piping needs, but the chemical properties involved.

Choosing PTFE lined pipe fittings is not always straightforward. Many options exist on the market, leading to potential confusion. Factors such as temperature limits, chemical compatibility, and installation requirements must all be considered. Often, users overlook these details, leading to costly mistakes.

PTFE lined pipe fittings are crucial in various industries. They are known for their chemical resistance and durability. These fittings can handle acids, bases, and solvents. The smooth surface minimizes friction, which enhances flow. However, a common mistake is overlooking the size and compatibility with existing systems.

When selecting PTFE lined fittings, consider your specific application. Think about pressure ratings and temperature limits. Many industries, like pharmaceuticals and food processing, require high standards. It’s essential to ensure that material specifications match your needs. Sometimes, buyers focus too much on price rather than fit and function. This can lead to issues down the line.

Inspection before installation is important. Check for any defects on the surface. Even minor imperfections can lead to failure. Don’t rush the process. Investing time in choosing the right fittings pays off. Remember, a fitting that seems perfect may not always perform as expected. It’s important to reflect on your choices for long-term success.

When selecting PTFE lined pipe fittings, several factors are critical. The chemical compatibility of the PTFE material is essential. Ensure that the lining will withstand the specific chemicals in your application. Some chemicals can degrade even high-quality PTFE. It’s crucial to verify this compatibility before proceeding with your choice.

Another important consideration is the temperature range. Different PTFE linings have distinct thermal tolerances. If your application involves extreme temperatures, confirm that the fittings can handle these conditions. Fittings that don’t meet the thermal requirements could fail. This could lead to costly downtime and potential safety hazards. Also, think about the pressure ratings. Ensure the fittings can manage the pressure within your system.

Finally, consider the installation process. Some fittings are more straightforward to install than others. Assess the complexities involved. If installation requires specialized tools or skills, it may complicate your project. Additionally, think about future maintenance needs. Accessibility can be a concern. In some cases, planning for maintenance could influence your initial selection. Evaluate these aspects carefully before making your final decision.

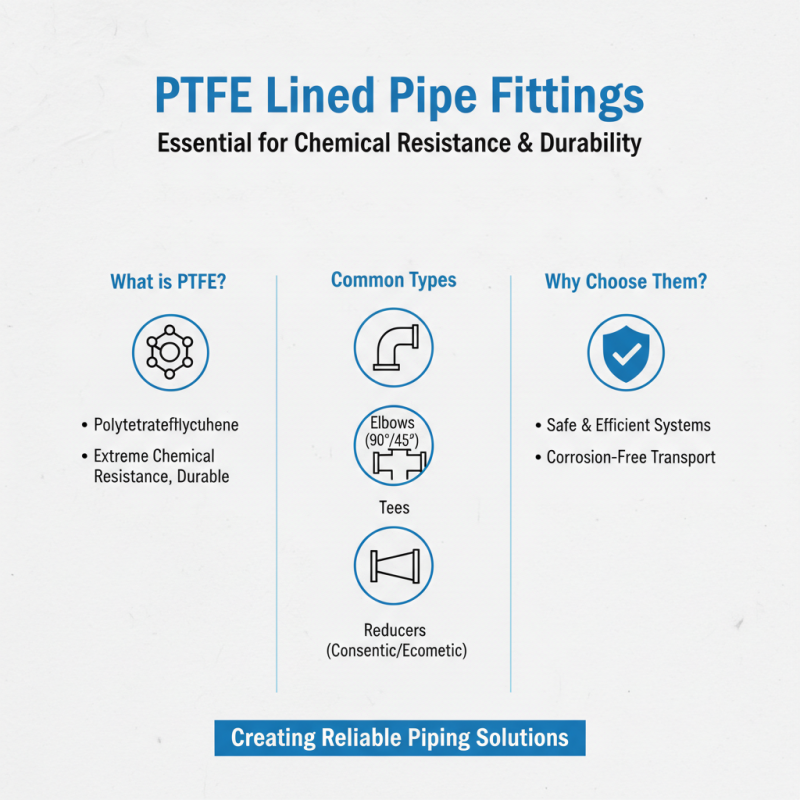

When choosing PTFE lined pipe fittings, it’s essential to understand the various types available. PTFE, or polytetrafluoroethylene, is known for its chemical resistance and durability. Common types of lined fittings include elbows, tees, and reducers. These fittings are crucial for creating safe and efficient piping systems.

Elbow fittings are designed to redirect flow. They come in various angles, typically 45 or 90 degrees. Tees allow for branching off pipes, making them ideal for complex routing. Reducers help in changing the diameter of the pipe system. It's vital to select the right fitting based on your specific needs.

You might encounter challenges when choosing specific types. Not all PTFE lined fittings will perform equally. Consider factors like temperature, pressure, and chemical compatibility. Testing smaller batches before full-scale implementation is always a wise decision. Each fitting plays a unique role, and oversight can lead to issues down the line. Ensure to evaluate your options thoroughly before making any commitments.

Evaluating the quality of PTFE lined pipe fittings is essential for optimal performance in various industries. Begin by inspecting the construction material. Check for the thickness and uniformity of the PTFE lining. A consistent lining prevents leaks and enhances durability. Feel the smoothness of the inner surface. A smoother surface often indicates better performance and lower resistance to flow.

Consider the fitting's specifications. Ensure they meet your industry standards. Look for certifications that verify quality and performance. It’s also valuable to understand the manufacturing process. Sometimes, the best-looking fittings may not perform well under pressure. Inspect the ends of the fittings. Uneven or rough edges can lead to problems during installation.

Test the fittings under actual conditions whenever possible. If feasible, take a sample to assess how it reacts to chemicals or high temperatures. Pay attention to any signs of degradation or failure. Discuss with experts or peers to gather insights about their experiences. Remember, not every fitting will meet every need perfectly. Learning from your evaluations and experiences is key for future purchases.

| Dimension | Specification | Material | Temperature Range (°C) | Pressure Rating (bar) | Application |

|---|---|---|---|---|---|

| 1/2 inch | ANSI 150 | PTFE | -200 to 260 | 10 | Chemical Processing |

| 3/4 inch | ANSI 150 | PTFE | -200 to 260 | 10 | Pharmaceuticals |

| 1 inch | ANSI 150 | PTFE | -200 to 260 | 10 | Food Processing |

| 1.5 inch | ANSI 150 | PTFE | -200 to 260 | 10 | Oil & Gas |

| 2 inch | ANSI 150 | PTFE | -200 to 260 | 10 | Water Treatment |

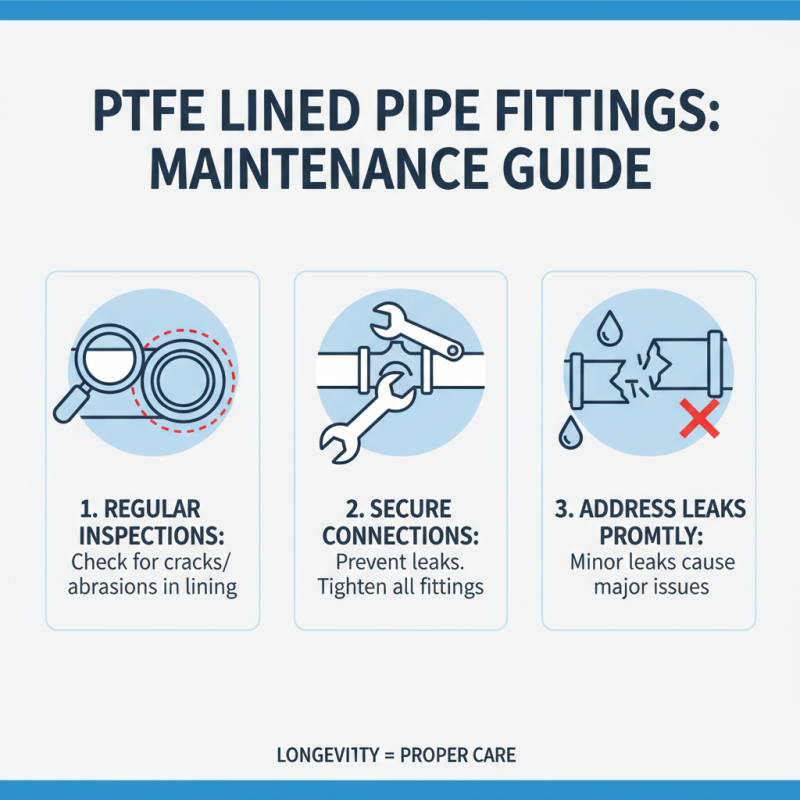

Proper maintenance of PTFE lined pipe fittings is crucial for their longevity. Regular inspections are necessary to identify any signs of wear or damage. Look for cracks or abrasions in the lining. Ensure that all connections are secure to prevent leaks. Even minor leaks can lead to bigger issues over time.

Cleaning these fittings is also essential. Use appropriate cleaning agents that won't harm the PTFE. High temperatures or abrasive materials can degrade the lining. Consider the operating conditions regularly. If your systems face fluctuations in pressure or temperature, adjustments to maintenance schedules may be needed.

Remember, maintenance is a proactive approach. Waiting until problems arise may result in increased downtime. Document all inspections and maintenance efforts. This helps in tracking performance over time. Engage with your team to discuss improvements in care. Reflect on past maintenance experiences to enhance future practices.