Email Id: sale@adctooling.com

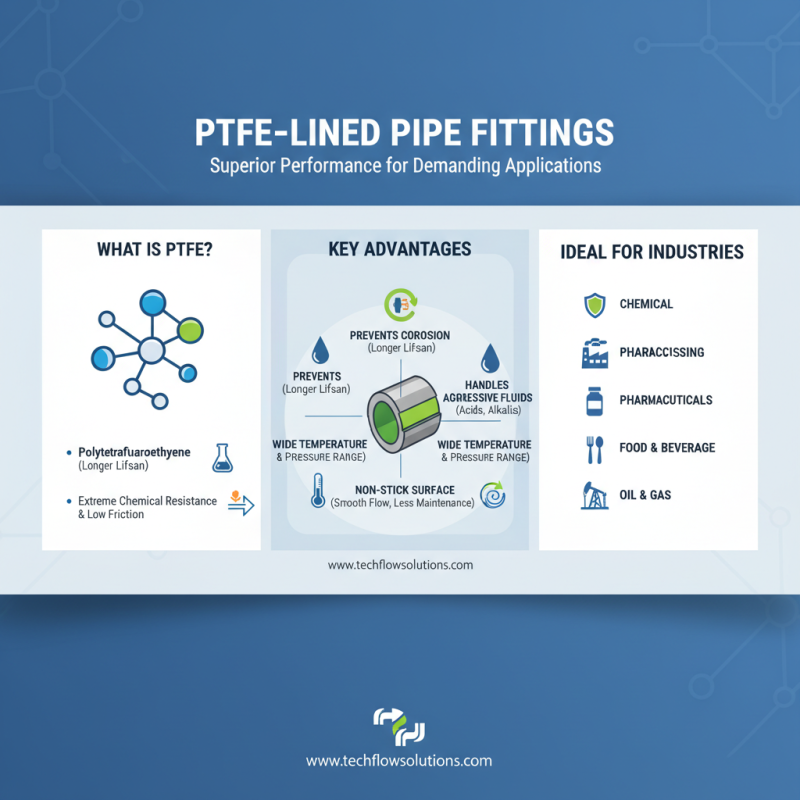

In the evolving landscape of industrial applications, the selection of appropriate piping components has become critical to ensuring operational efficiency and longevity. Among these components, PTFE lined pipe fittings stand out due to their exceptional chemical resistance and versatility in handling various substances. According to a recent industry report by Research and Markets, the global market for PTFE lined pipe fittings is projected to grow significantly, driven by increasing demand across sectors such as chemicals, pharmaceuticals, and oil and gas. This growth is attributed to the need for reliable materials that can withstand aggressive environments and reduce maintenance costs.

When choosing the best PTFE lined pipe fittings for specific applications, several factors should be considered, including temperature and pressure ratings, compatibility with media, and environmental conditions. A 2021 study published in the Journal of Materials Science highlights the importance of selecting fittings that not only meet the operational parameters but also align with safety standards and sustainability goals. By understanding the unique properties of PTFE lined fittings and how they cater to particular needs, industries can enhance performance and extend the lifespan of their piping systems.

PTFE, or polytetrafluoroethylene, is a high-performance plastic renowned for its exceptional chemical resistance and low friction properties. In pipe fittings, PTFE lined options offer the advantage of preventing corrosion, which is a significant concern in many industrial applications. This makes PTFE lined pipe fittings ideal for transporting aggressive fluids, as they can withstand a wide range of temperatures and pressures without deteriorating. The inherent non-stick qualities of PTFE also ensure smooth flow and reduced maintenance, making these fittings a favored choice in various sectors.

When selecting PTFE lined pipe fittings, consider a few key tips to ensure you make the best choice for your specific needs. Firstly, evaluate the compatibility of PTFE with the fluids you plan to transport. Not all materials behave the same way with PTFE, so it's crucial to understand the chemical interactions involved. Secondly, examine the pressure and temperature ratings of the fittings to ensure they align with your operational requirements. Lastly, consider the fitting configuration, as the right shape and size will enhance efficiency and performance in your piping system.

The advantages of PTFE do not end with chemical resistance; its insulating properties make it suitable for applications in sensitive environments as well. By minimizing risk of contamination and enabling a longer lifespan for your fittings, PTFE lined options can save both time and money in the long run.

When selecting PTFE lined pipe fittings, several key factors should be taken into account to ensure they meet your specific needs. First and foremost, consider the chemical compatibility of PTFE with the substances that will flow through the pipes. PTFE is renowned for its excellent chemical resistance, but understanding the specific chemicals in use will help you avoid any potential degradation or failure of the fittings. This includes evaluating factors such as temperature and pressure conditions, as these can also influence the material's performance.

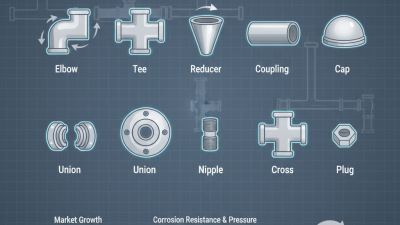

Another critical factor to consider is the fitting size and dimensions. Ensuring that the fittings are compatible with your existing piping system is crucial for maintaining efficiency and safety. Proper alignment and sealing are essential to prevent leaks, so attention should be paid to the exact specifications, including diameter and length. Lastly, installation requirements and ease of maintenance should not be overlooked. Selecting fittings that can be easily installed and serviced will enhance your operational efficiency and reduce downtime, making it a vital aspect of the decision-making process.

PTFE lined pipe fittings are crucial components across various industries due to their excellent resistance to corrosive substances and ability to handle high temperatures. Common applications include chemical processing, pharmaceuticals, and food and beverage industries, where ensuring safe and contamination-free transport of materials is essential. In chemical processing, PTFE lined fittings facilitate the movement of aggressive chemicals, while in pharmaceuticals, they maintain strict hygiene standards, ensuring that processing does not compromise product integrity.

When selecting PTFE lined pipe fittings, consider the specific requirements of your application. Ensure that the fittings are rated for both the temperature and pressure of the system to avoid potential failures. Additionally, compatibility with the carried substances is vital; improper selections could lead to degradation over time.

Tips: When selecting fittings, always consult with manufacturers or professionals who can provide insights on the best materials for your specific needs. Furthermore, regular maintenance and inspection can help extend the lifespan of PTFE lined fittings, ensuring they continue to perform optimally in demanding environments. Lastly, consider the installation process carefully to prevent leaks and ensure a long-lasting system.

When assessing pipe fittings for industrial applications, a comparative analysis of PTFE lined pipe fittings versus traditional alternatives reveals significant performance advantages. PTFE, or polytetrafluoroethylene, is renowned for its exceptional chemical resistance and ability to withstand high temperatures, making it an ideal choice for corrosive environments. According to a report by the International Journal of Chemical Engineering, PTFE lined fittings exhibit a lifespan at least five times longer than standard metal fittings when exposed to aggressive chemicals, thus reducing replacement costs in the long run.

Moreover, the friction coefficient of PTFE lined fittings is much lower than that of traditional materials, which can enhance fluid flow efficiency. A study published by the American Society of Mechanical Engineers indicates that utilizing PTFE linings can decrease fluid resistance by up to 30%, resulting in lower energy consumption and enhanced operational performance. As industries increasingly emphasize sustainability and cost-effectiveness, the shift towards PTFE lined fittings becomes more apparent, driven by not only their longevity but also their role in optimizing energy utilization in fluid transport systems.

| Feature | PTFE Lined Pipe Fittings | Traditional Pipe Fittings |

|---|---|---|

| Temperature Resistance | -200°C to 260°C | Up to 150°C |

| Chemical Resistance | Excellent against most chemicals | Limited, varies by material |

| Corrosion Resistance | Very high | Depends on material |

| Installation Cost | Higher due to specialized skills | Generally lower |

| Maintenance | Low maintenance | Moderate to high |

| Longevity | 20+ years | 10-15 years |

| Application Areas | Pharmaceuticals, Food Processing | Water Supply, General Plumbing |

When it comes to maintaining PTFE lined pipe fittings, regular inspection and cleaning are essential to preserving their lifespan and ensuring optimal performance. According to the Plastics Pipe Institute, these fittings can handle temperatures up to 260°C (500°F) and are resistant to a wide range of chemicals, making them suitable for various industrial applications. However, factors such as pressure fluctuations, exposure to abrasive materials, and inadequate maintenance can lead to premature wear and tear.

To extend the lifespan of PTFE lined pipe fittings, it is crucial to implement a scheduled maintenance routine. This includes visually inspecting the fittings for signs of damage, leaks, or chemical degradation. Additionally, routine cleaning with appropriate solvents can help prevent buildup that may cause blockages or corrosion. The American Society of Mechanical Engineers (ASME) recommends using non-abrasive cleaning agents to preserve the integrity of the PTFE lining. Moreover, tight monitoring of operational conditions, such as temperature and pressure, can prevent mechanical stress that may shorten the fittings' lifespan. Regular assessments and adherence to industry standards will ensure that PTFE lined pipe fittings operate efficiently for years.