Email Id: sale@adctooling.com

Choosing the right pipe plug is a critical decision for various industries, especially in plumbing, construction, and manufacturing. According to a report by the American Society of Mechanical Engineers (ASME), inadequate sealing can lead to significant operational issues, including leaks that may cause safety hazards and costly repairs. The global pipe plug market is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing demand for effective sealing solutions across multiple applications.

When selecting a pipe plug, it is essential to consider factors such as the type of materials being sealed, the pressure and temperature conditions of the environment, and the specific application requirements. The right pipe plug not only ensures a tight seal but also optimizes performance and enhances the longevity of plumbing systems. A misstep in choosing the correct pipe plug can result in downtime, increased maintenance costs, and potential safety risks. This underscores the importance of understanding the various features and specifications that pipe plugs offer, which will ultimately lead to better decision-making and operational success.

When it comes to selecting the right pipe plug for your specific needs, it's essential to understand the variety of options available and their respective applications. Pipe plugs are designed to seal off pipe openings in various industrial and residential settings. Common types include mechanical, inflatable, and threaded pipe plugs, each serving distinct purposes. Mechanical plugs are ideal for standard sealing tasks, while inflatable plugs provide flexibility for irregular shapes and sizes. Threaded plugs, on the other hand, are advantageous for high-pressure systems where a secure fit is crucial.

One important tip when choosing a pipe plug is to consider the diameter and material of the pipe. Ensure the plug matches the pipe size to prevent leaks. Additionally, think about the environmental conditions—whether the material will withstand heat, chemicals, or moisture. Another crucial factor is the ease of installation. Some plugs require special tools, while others can be installed manually without much effort.

Ultimately, assessing the application where the plug will be used helps narrow down the options, ensuring you select the most efficient and effective product for the task at hand.

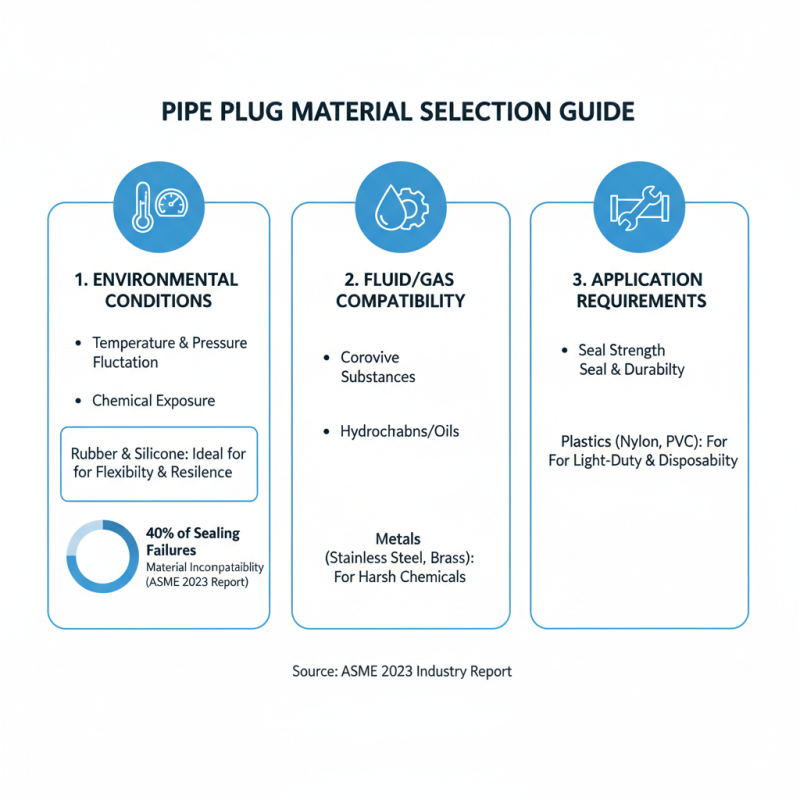

When selecting the appropriate material for pipe plugs, several key factors come into play that can significantly impact performance and reliability. One of the most important considerations is the environment in which the pipe plug will be used. For instance, materials such as rubber or silicone are often preferred for applications where flexibility and resilience are needed, particularly in situations involving variations in temperature and pressure. According to a 2023 industry report by the American Society of Mechanical Engineers, nearly 40% of failures in sealing applications are attributed to the incompatibility of plug materials with environmental conditions.

Another critical factor is the chemical compatibility of pipe plug materials with the fluids they will encounter. In operations where aggressive chemicals are present, materials such as PTFE or certain grades of stainless steel should be considered, as they provide enhanced resistance to corrosion and degradation. A survey conducted by the Chemical Engineering Society indicated that the selection of chemically resistant materials can increase lifespan and operational efficiency by up to 30%, thereby reducing frequent replacements and maintenance costs.

Lastly, pressure ratings should not be overlooked, as different materials have varying pressure thresholds. It’s essential to ensure that the chosen pipe plug can handle the pressure experienced within the pipeline. The National Institute of Standards and Technology reported that improper selection of pressure-rated materials has been responsible for over 20% of pipeline incidents in recent years, underscoring the importance of thorough material assessment to avoid failures. By understanding these key factors, users can make informed decisions that enhance the safety and efficacy of their piping systems.

When selecting the right pipe plug, one of the most critical factors to consider is sizing and compatibility. It is essential to accurately measure the diameter of the pipe where the plug will be used, as a proper fit is crucial for achieving maximum seal integrity. Using a plug that is either too large or too small can result in leaks, which not only undermines the purpose of sealing but can also lead to more extensive damage and costly repairs. Ensure you have reliable measurements and refer to product specifications to find the perfect match.

Another vital aspect of compatibility involves the material of the pipe and the plug itself. Different materials exhibit varying levels of durability and resistance to substances such as chemicals, heat, and pressure. For instance, a rubber plug may not withstand the same conditions as a metal one. Therefore, understanding the specific requirements of your application will help you choose a plug that not only fits but also performs effectively under the expected conditions. This attention to detail will safeguard the integrity of your system and ensure a long-lasting, reliable seal.

When selecting the appropriate pipe plug for specific applications, it is crucial to consider the industry standards and regulations that govern their use. Organizations such as the American Society for Testing and Materials (ASTM) and the National Fire Protection Association (NFPA) provide guidelines that help ensure safety and efficiency in plugging systems. According to a report by the American National Standards Institute (ANSI), adherence to these standards can significantly minimize risks associated with leaks and pressure variances, which can lead to catastrophic failures in pipelines.

Moreover, the compliance with regulations like the Occupational Safety and Health Administration (OSHA) standards impacts pipe plug selection by mandating certain requirements for materials and performance. For instance, materials that can withstand specific temperature and pressure ratings are crucial to meet these regulations. A study conducted by the International Organization for Standardization (ISO) indicated that over 60% of industrial incidents related to pipe failures could have been prevented with appropriate material certification and adherence to recognized standards. Therefore, understanding and applying industry regulations is a fundamental part of ensuring that the chosen pipe plug not only meets operational needs but also promotes safety and reliability within the system.

When utilizing pipe plugs, maintenance and safety should be paramount. According to a report by the American Society of Civil Engineers, improper handling and installation of pipe plugs can lead to significant leaks and failures, costing industries thousands in repairs and downtime. To mitigate these risks, it is essential to regularly inspect pipe plugs for wear and damage, ensuring they meet the required specifications for the intended application.

One key tip for effective use is to ensure that the plug is compatible with the pipe material. Many issues arise when unsuitable plugs are used, leading to material degradation and unsafe conditions. Data from the National Institute of Standards and Technology indicates that using the correct type of pipe plug can enhance sealing effectiveness by up to 30%, thereby preventing potential leaks and environmental hazards.

Furthermore, always follow the manufacturer's guidelines for installation and pressure ratings. Over-pressurizing a pipe plug may result in catastrophic failure. For instance, studies have shown that exceeding the rated pressure can lead to incidents that not only harm equipment but also create safety risks for personnel. Regular training and clear protocols enhance the effectiveness of pipe plugs in various applications while ensuring the safety of all involved.