Email Id: sale@adctooling.com

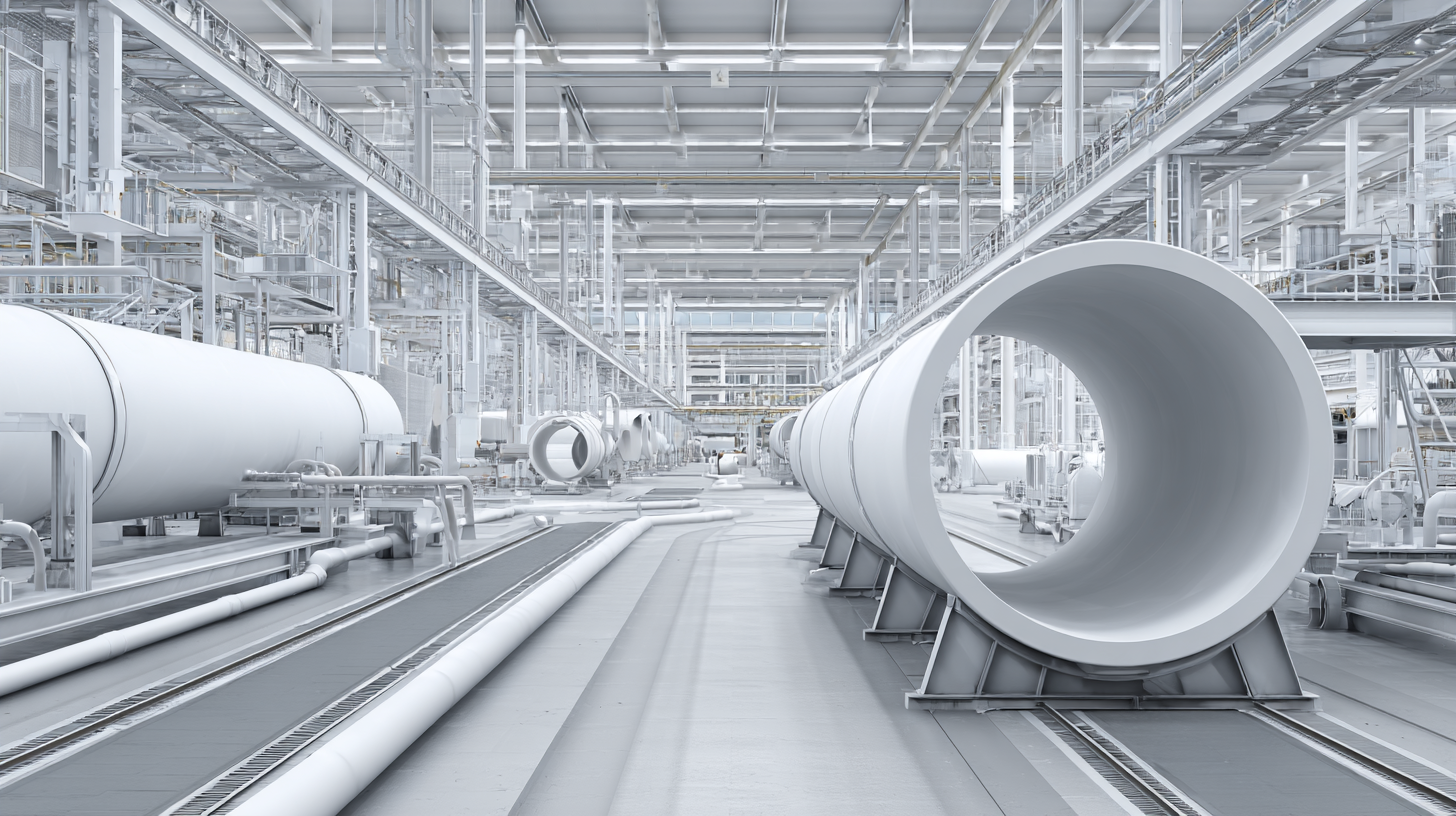

As the global demand for advanced materials continues to rise, the PTFE pipe market is set for significant innovations by 2025, positioning itself as a key player in various industries. According to a recent report by Grand View Research, the global PTFE market size is expected to reach USD 2.45 billion by 2025, driven by the increasing adoption of fluoropolymers in chemical processing and manufacturing sectors. The unique properties of PTFE pipes, such as their exceptional chemical resistance and high thermal stability, make them indispensable for applications in pharmaceuticals, food processing, and petrochemicals.

With top manufacturers in China leading the charge, the advancements in PTFE pipe technology promise not only enhanced durability and efficiency, but also sustainability benefits, ultimately fostering greater trust among global buyers. In this blog, we will explore the future innovations in PTFE pipe technology and their far-reaching benefits for industries worldwide.

The evolution of PTFE pipe production technology is set to make significant strides by 2025, influenced by the growing demand for high-performance materials across various industries. One of the most noteworthy trends is the adoption of advanced manufacturing techniques, such as 3D printing and precision machining. These methods not only enhance the efficiency and accuracy of pipe production but also allow for customization in dimensions and design, catering to the specific needs of global buyers.

The evolution of PTFE pipe production technology is set to make significant strides by 2025, influenced by the growing demand for high-performance materials across various industries. One of the most noteworthy trends is the adoption of advanced manufacturing techniques, such as 3D printing and precision machining. These methods not only enhance the efficiency and accuracy of pipe production but also allow for customization in dimensions and design, catering to the specific needs of global buyers.

Another emerging trend is the incorporation of sustainable practices within PTFE pipe manufacturing. As environmental concerns continue to rise, manufacturers are increasingly focusing on reducing waste and energy consumption during production. This shift towards sustainability will not only lessen the ecological impact but also appeal to buyers who prioritize eco-friendly solutions. Furthermore, innovations in recycling systems for PTFE materials are expected to gain traction, making it easier for industries to repurpose spent materials and contribute to a circular economy.

Lastly, the integration of smart technologies into PTFE pipe production is on the horizon. Utilizing IoT and AI for real-time monitoring and predictive maintenance will enhance product quality and durability. Buyers will benefit from reduced downtime and maintenance costs, leading to more reliable operations. As these trends unfold, global buyers will find themselves equipped with more efficient, sustainable, and technologically advanced PTFE piping solutions to meet their evolving needs in 2025 and beyond.

As industries continue to evolve, the demand for advanced materials such as PTFE (polytetrafluoroethylene) pipes is on the rise. Renowned for their excellent chemical resistance and thermal stability, PTFE pipes are becoming essential in various applications, including pharmaceuticals, food processing, and petrochemical sectors. These innovative pipes not only withstand aggressive chemicals but also ensure minimal contamination, making them highly desirable for industries requiring stringent hygiene standards.

In addition to their superior chemical properties, PTFE pipes offer remarkable flexibility and low friction, which enhances fluid flow efficiency. This characteristic is particularly beneficial in systems where pressure drops need to be minimized. Furthermore, the advanced manufacturing techniques being employed in 2025 are expected to improve the sustainability of PTFE pipes, making them an environmentally friendly option. Global buyers can anticipate significant cost savings over time due to reduced maintenance needs and increased durability, ensuring that PTFE technology will play a crucial role in the future of industrial piping solutions.

As the world increasingly prioritizes sustainability, the PTFE (polytetrafluoroethylene) pipe industry is adapting its manufacturing processes to meet environmental standards. Innovations in material sourcing and production techniques are expected to be key in 2025. According to a report by Global Market Insights, the global PTFE market is projected to surpass $2 billion by 2025, driven not only by demand for high-performance materials but also by a growing emphasis on eco-friendly practices. Manufacturers are now focusing on minimizing waste and enhancing recyclability, thereby reducing the environmental footprint of PTFE products.

To achieve sustainability in PTFE pipe manufacturing, companies are investing in advanced technologies such as green chemistry and water-based processes. These initiatives help to lower volatile organic compounds (VOC) emissions significantly. A recent study published by the American Institute of Chemical Engineers underscores that adopting sustainable manufacturing practices can reduce production costs by up to 20%, illustrating a win-win scenario for both the environment and companies’ bottom lines.

Tip: When considering PTFE pipe suppliers, look for certifications that validate their commitment to environmentally friendly practices. Such certifications not only ensure compliance with environmental standards but also reflect a supplier's ongoing efforts to innovate sustainably.

| Innovation | Description | Benefits | Environmental Impact |

|---|---|---|---|

| Biodegradable PTFE Alternatives | Development of new materials that offer the same chemical resistance while being environmentally friendly. | Reduced environmental footprint, enhanced recyclability. | Lower persistence in landfills, positive impact on waste management. |

| Enhanced Energy Efficiency | Innovations focused on reducing energy requirements during manufacturing and operation. | Cost savings for manufacturers and users, improved operational efficiency. | Lower greenhouse gas emissions through reduced energy consumption. |

| Smart Sensor Integration | Incorporation of sensors into PTFE pipe systems for real-time monitoring of flow and pressure. | Improved maintenance, reduced leakage and downtime. | Enhanced resource management and preventive maintenance results in lower environmental impact. |

| Recycled Material Use | Utilizing recycled PTFE in new manufacturing processes. | Reduction in raw material usage and costs, supporting a circular economy. | Lower demand for virgin materials, decreased resource extraction impact. |

| Advanced Coating Technologies | New coatings that enhance durability and resistance to corrosion and fouling. | Extended life span of pipes, reduced maintenance needs. | Less frequent replacements lead to reduced waste and resource use over time. |

In 2025, the advancements in PTFE (polytetrafluoroethylene) pipe technology are expected to redefine cost-effectiveness in global markets. Manufacturers are now focusing on innovative production methods that not only lower material costs but also enhance the overall performance of PTFE pipes. By investing in state-of-the-art manufacturing techniques, companies can produce lighter and more durable pipes, resulting in substantial savings for buyers. As these innovations are adopted, the financial advantages of choosing PTFE pipes over traditional materials will become increasingly apparent.

Moreover, the long-lasting nature of PTFE pipes contributes to their cost-effectiveness. With exceptional resistance to corrosion and chemicals, PTFE pipes require significantly less maintenance over their lifespan. This longevity reduces the need for frequent replacements and repairs, translating to lower total ownership costs. Global buyers can benefit from these economical solutions as they search for reliable piping options that not only meet their immediate needs but also align with their long-term financial strategies. The integration of cutting-edge technology with traditional values will set the stage for a new era in PTFE pipe applications, further solidifying their role as a smart investment in various industries.

When selecting PTFE pipes for projects in 2025, there are several key factors that global buyers should prioritize to ensure optimal performance and reliability. Firstly, the chemical resistance of PTFE makes it suitable for a wide range of applications, particularly in industries requiring high purity and durability. Buyers should assess the specific chemical exposure relevant to their projects to select pipes that will withstand harsh conditions without compromising integrity.

Moreover, the temperature resistance capabilities of PTFE pipes can significantly impact their utility. Prospective buyers should check the operational temperature limits to ensure that the pipes will perform efficiently in their intended environments. Additionally, understanding the pressure rating of the selected PTFE pipes is vital for applications that involve the transportation of fluids under varying pressure conditions.

Tips: When assessing PTFE pipes, always request samples to evaluate their flexibility and ease of installation. Also, consider suppliers who offer comprehensive warranties and support, as this can significantly enhance long-term project success. Lastly, keep an eye on market trends and innovations in PTFE technology, as advancements could provide new solutions and efficiencies for your projects.