Email Id: sale@adctooling.com

Choosing the right PTFE lined valves for your applications is critical for optimal performance. According to a recent industry report by Global Market Insights, the market for PTFE lined valves is projected to reach $1 billion by 2026. This growth is driven by their resistance to corrosive environments. Experts emphasize that proper selection is crucial. Dr. Jane Smith, a leading authority in the field, states, “Selecting the right PTFE lined valve can significantly enhance system reliability.”

When considering PTFE lined valves, users must evaluate specific application needs. Factors such as pressure ratings, temperature limits, and chemical compatibility play vital roles in decision-making. It’s important to remember that not all PTFE lined valves are the same. Some may not perform as expected under specific conditions. Thorough research ensures that the selected valve meets industry standards, reducing the risk of failure.

In addition, users should be aware of the long-term implications of their choices. Investing in high-quality PTFE lined valves can minimize maintenance costs and downtime. However, many overlook the importance of after-sales support. Without adequate assistance, even the best products may underperform. Choosing PTFE lined valves is more art than science, requiring careful consideration and expert guidance.

PTFE lined valves are essential in various industries, providing effective solutions for managing aggressive chemicals. Understanding their construction is crucial. PTFE, or polytetrafluoroethylene, is a high-performance plastic that offers excellent resistance to heat, corrosion, and chemical degradation. These valves employ a lining that protects the valve body, ensuring longevity and reliability.

When selecting PTFE lined valves, consider the specific requirements of your application. Think about the temperature and pressure conditions. Will the valve handle strong acids or bases? The wrong choice can lead to failures or leaks. Thus, thorough understanding is important. Each application demands careful analysis of the chemical compatibility of PTFE with substances in your process.

Regular maintenance cannot be overlooked. Even durable materials might degrade under certain conditions. A well-maintained valve will serve longer and reduce downtime. Considering the long-term implications can help in decision-making. Often, it is easy to overlook nuances. Reflect on past experiences to make informed choices in the future.

When selecting PTFE lined valves, consider the application requirements. Think about the temperature and pressure limits. PTFE can handle high temperatures, but not all valves are designed for extreme conditions. Examine your fluid's compatibility with PTFE. High concentrations of certain chemicals can degrade the lining over time.

Material quality is crucial. Look for durable construction to prevent leaks. Evaluate the valve type; different designs suit different applications. Some may offer better sealing, while others are easier to maintain. Focus on the intended flow direction. This might seem minor but can impact performance significantly.

Installation is another aspect. Ensure there's enough space for placement. A poorly installed valve can lead to failures. Remember, PTFE is not the only material available. Sometimes, alternatives might offer better longevity or cost-effectiveness. Reflect on your needs thoroughly before making a decision. Each detail counts in ensuring the right fit for your application.

| Factor | Description | Importance Rating (1-5) |

|---|---|---|

| Temperature Resistance | Ability to function in high temperature environments without degradation. | 5 |

| Chemical Compatibility | Suitability for the specific chemicals being transported through the valve. | 5 |

| Pressure Ratings | Ability to withstand the pressure conditions of your application. | 4 |

| Size and Dimensions | The physical size of the valve and its compatibility with existing piping. | 3 |

| End Connections | Type of end connections required for integration into systems. | 4 |

| Maintenance Requirements | Ease of maintenance and servicing needs for the valve. | 3 |

| Cost | Initial purchasing cost as well as long-term operational costs. | 4 |

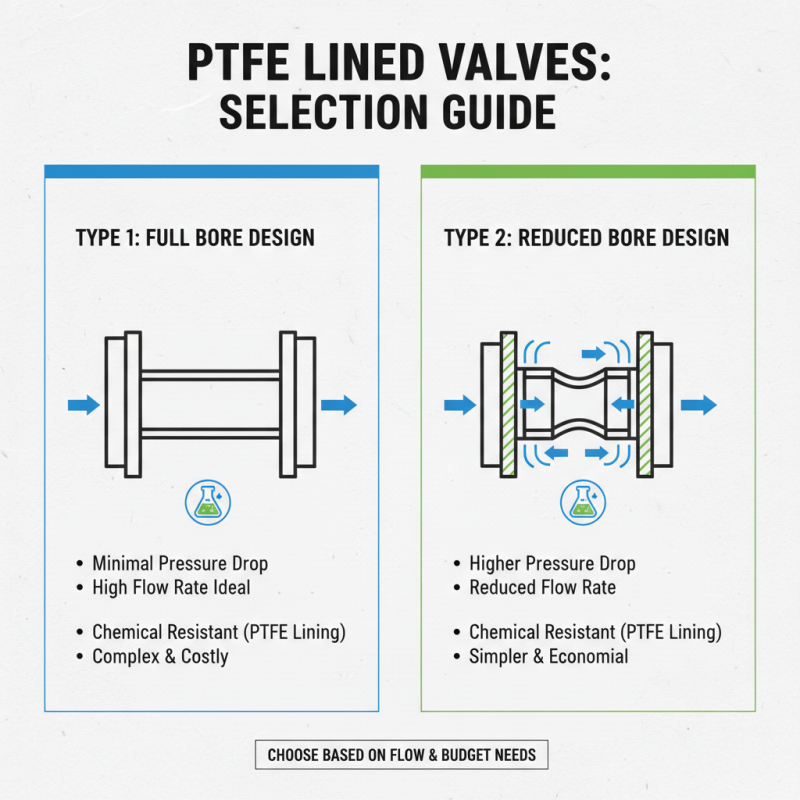

When selecting PTFE lined valves, it’s essential to understand the different types available. PTFE, known for its chemical resistance, is a popular choice. One option is the full bore design, which offers minimal pressure drop. This design is beneficial in applications where flow rate is crucial. However, it can be more expensive and complex.

Another type is the reduced bore valve. It is more economical but may lead to increased turbulence, affecting flow performance. Some industries favor this type because of its cost-effectiveness. Still, it’s vital to consider if the flow characteristics align with application needs.

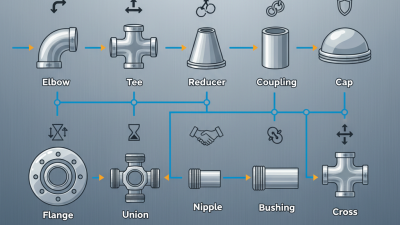

Flanged and threaded connections are also common in PTFE lined valves. Flanged valves are easier to maintain but require more space. Threaded valves are compact, but installation can be tricky. Choosing the right connection type depends on installation space and maintenance preferences. Each option presents unique advantages and disadvantages, making it necessary to assess requirements carefully.

PTFE lined valves require specific maintenance to ensure optimal performance in industrial settings. Regular inspections are crucial. Check for signs of wear and tear on the valve lining. Cracks or abrasions may lead to leaks. Watch for unusual noises during operation. These can indicate internal issues.

Cleaning is another significant aspect of maintenance. Use gentle cleaning solutions to avoid damaging the PTFE lining. Avoid abrasive tools, as these can cause scratches. A soft cloth or brush is often enough. After cleaning, ensure that the valve is thoroughly dried. Moisture can lead to corrosion and damage.

It's essential to keep records of all maintenance activities. Note down any repairs or replacements made. Reflecting on past maintenance can help identify recurring issues. This is vital for avoiding future problems. Sometimes, we overlook minor details. Keeping a keen eye on these can improve the valve's overall lifespan.

When selecting PTFE lined valves, avoiding common mistakes is crucial. Many tend to overlook the specific requirements of their applications. Each industry has unique needs. For example, chemicals and temperature ranges should guide your choice.

An often overlooked factor is compatibility. Not all PTFE materials are made equal. Some might not withstand certain chemical environments. This mistake can lead to unexpected failures and costly downtime. Always check the corrosion resistance of your chosen valve.

Tips: Consider the valve size; it impacts flow rates. Improper sizing can cause inefficiencies. Also, ensure you have the right fittings. Mismatched components can result in leaks. Lastly, consult with experts if you're unsure. Their insights can save you from costly misjudgments.