Email Id: sale@adctooling.com

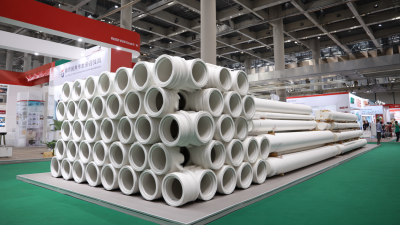

When it comes to selecting the right PTFE pipe fittings for your project, understanding the nuances of this specialized material can make a significant difference in performance and durability. According to industry expert John Smith, a leading consultant in fluid dynamics, "Choosing the right PTFE pipe fittings is crucial, as they must withstand not only high temperatures but also aggressive chemicals without failure." This statement underlines the importance of careful consideration in the selection process.

PTFE, or polytetrafluoroethylene, is renowned for its exceptional resistance to chemical corrosion and high temperatures, making it a preferred choice in various industrial applications. The decision-making process involves evaluating factors like compatibility with the fluid being transported, pressure requirements, and installation conditions. By following critical tips and insights, one can ensure that the right PTFE pipe fittings will enhance the overall efficiency and safety of any project.

In this article, we will delve into the top 10 tips that will guide you in choosing the most suitable PTFE pipe fittings, tailored to meet the specific needs of your application. Whether you're working in chemical processing, pharmaceuticals, or food production, these tips will help you make informed decisions that align with industry best practices.

When selecting PTFE pipe fittings for your project, understanding the unique properties of PTFE (Polytetrafluoroethylene) is crucial. PTFE is renowned for its exceptional chemical resistance, low friction coefficient, and ability to withstand extreme temperatures. These characteristics make it an ideal choice for applications in industries such as pharmaceuticals, food processing, and chemical manufacturing. The non-reactive nature of PTFE ensures that it will not contaminate the substances it carries, maintaining the integrity of your system.

One important tip is to consider the temperature and pressure ratings of the PTFE fittings you choose. Ensure they align with your project's specific requirements to prevent failures. Additionally, evaluate the fitting's compatibility with the associated piping materials to achieve a secure and leak-proof connection. Another tip is to verify the manufacturer's certifications and quality standards to guarantee that the PTFE fittings meet the necessary regulations for your application. This diligence will significantly contribute to the safety and efficiency of your piping system.

When selecting PTFE pipe fittings for your project, the first step is to identify your specific requirements. Consider the medium that will flow through the pipes; factors such as temperature, pressure, and chemical compatibility are crucial. For instance, if you’re working with aggressive chemicals, ensure that the PTFE fittings are rated for chemical resistance to avoid degradation over time. Additionally, high-temperature applications may require fittings that can withstand sustained exposure to elevated temperatures without loss of integrity.

Next, assess the dimensions and configuration needed for your project. Accurate measurements of pipe diameter and fitting size are essential to guarantee a proper fit and prevent leaks. Consider the installation environment as well—if the fittings will be subjected to high stress or vibration, opt for designs that enhance mechanical stability. Thoroughly understanding these requirements not only facilitates a smoother installation process but also ensures optimal performance and longevity of your piping system.

When selecting PTFE pipe fittings for your project, evaluating their compatibility with the fluids they will handle is crucial. PTFE, known for its excellent chemical resistance, is often used in applications involving aggressive fluids. Be sure to identify the specific chemicals and their concentrations, as some substances may degrade certain types of PTFE, potentially leading to leaks or system failures.

One important tip is to consult the manufacturer’s compatibility charts or guidelines. These resources provide valuable information about how PTFE fittings react with various chemicals, aiding in the selection of fittings that will perform reliably under specific conditions. Additionally, consider the temperature and pressure requirements of the fluid system, as PTFE fittings have different performance thresholds based on these factors.

Another recommendation is to evaluate the fitting's design and connection type. Different applications may require various joint configurations, such as threaded, welded, or flanged connections. Selecting the right type not only ensures a leak-free connection but also enhances overall system integrity. Remember, proper sealing techniques can further improve performance and longevity of PTFE fittings in your applications.

When it comes to selecting the right PTFE pipe fittings for your project, understanding the variety of options available is crucial. PTFE (polytetrafluoroethylene) fittings are known for their exceptional resistance to corrosion and high temperatures, making them ideal for chemical processing, food manufacturing, and pharmaceutical applications. According to industry reports, the global PTFE fittings market is projected to grow significantly, driven by the increasing demand for durable and reliable piping solutions in various industries.

In comparing different types of PTFE pipe fittings, it's essential to consider their configurations, such as straight, elbow, and tee fittings, as each serves a distinct purpose in fluid transfer. For instance, elbow fittings are commonly used to change the direction of the flow, while tee fittings allow branching in multiple directions. Additionally, the choice between different grades of PTFE—like virgin PTFE and filled PTFE—can impact performance and cost. Studies show that filled PTFE offers enhanced wear resistance, making it suitable for applications with high abrasion levels, while virgin PTFE is preferred for its purity in sensitive applications. Understanding these specifications will help in making informed decisions that align with your project's requirements.

| Type of PTFE Fitting | Temperature Resistance (°C) | Pressure Rating (psi) | Chemical Compatibility | Applications |

|---|---|---|---|---|

| PTFE Elbow | -200 to 260 | 150 | Highly compatible with acids, bases, and organic solvents | Chemical processing, fluid transfer |

| PTFE Tee | -200 to 260 | 150 | Resistant to most chemicals | Water treatment, food processing |

| PTFE Union | -200 to 260 | 150 | Excellent resistance to corrosive fluids | Pharmaceuticals, petrochemicals |

| PTFE Reducer | -200 to 260 | 150 | Compatible with a wide range of chemicals | Piping systems, HVAC |

| PTFE Bushing | -200 to 260 | 150 | Resistant to many corrosive agents | Mechanical engineering, chemical storage |

| PTFE Cap | -200 to 260 | 150 | Outstanding resistance to oxidation | Oil and gas, environmental applications |

| PTFE Flange | -200 to 260 | 150 | Highly resistant to corrosive chemicals | Industrial piping, waste management |

| PTFE Socket | -200 to 260 | 150 | Compatible with various solvents and acids | Laboratory applications, chemical processing |

| PTFE Nipple | -200 to 260 | 150 | Resistant to heat and chemicals | Fluid transfer, hydraulic systems |

When selecting PTFE pipe fittings for your project, it is crucial to assess the quality and reliability of manufacturers and suppliers. In an industry where precision and durability are paramount, the credentials of the supplier can significantly influence the success of your application.

Start by conducting thorough research. Look for manufacturers with a proven track record and positive customer reviews, as these indicators can provide insights into their product reliability.

Furthermore, certifications play a vital role in establishing credibility. Opt for suppliers who adhere to industry standards and possess relevant certifications, as these demonstrate their commitment to quality and performance. Evaluating the supply chain stability is equally important; understand potential risks that may arise from interruptions, which can impact delivery timelines.

A reliable supplier should not only deliver high-quality products but also maintain a consistent supply, ensuring that your project proceeds smoothly and meets its deadlines.