Email Id: sale@adctooling.com

When embarking on a new construction or plumbing project, selecting the right materials is crucial for ensuring durability and efficiency. Among these materials, steel pipe fittings play a vital role in creating robust and reliable connections between pipes. Whether you're working on a minor repair or a major infrastructure project, understanding the various types and applications of steel pipe fittings can significantly influence the success of your endeavor.

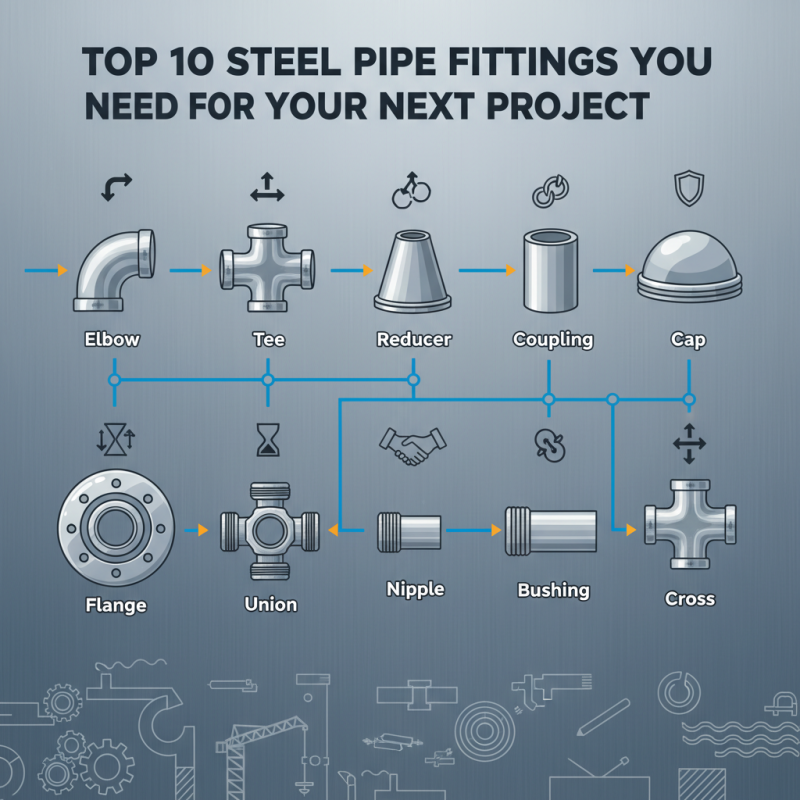

In this guide, we will explore the top 10 steel pipe fittings that are essential for your next project. With a diverse range of shapes, sizes, and functionalities, these fittings cater to a wide array of construction needs. From enhancing fluid flow to providing structural integrity, the proper selection of steel pipe fittings can make a substantial difference in performance and safety. By familiarizing yourself with these indispensable components, you can ensure that your project not only meets industry standards but also stands the test of time.

When embarking on a construction project, selecting the right steel pipe fittings is crucial for ensuring structural integrity and functionality. Steel pipe fittings serve as essential components that connect, redirect, and manage the flow of liquids or gases in various systems. Among the essential types, some fittings stand out due to their versatility and adaptability across multiple applications.

Elbows and tees are fundamental for changing the direction of fluid flow. Elbows, whether at 45 or 90 degrees, allow seamless turns in piping systems, making them indispensable for layouts that require redirection. Tees, on the other hand, are essential for branching off the main line, allowing for the distribution of fluids to multiple directions. Additionally, couplings and unions are vital for connecting two pipe segments. Couplings offer a permanent connection, while unions allow for ease of disassembly, enabling maintenance without the need for cutting pipes.

Adapters also play a significant role, particularly when transitioning between different pipe sizes or materials. They ensure compatibility across various systems, enhancing the project’s efficiency. For scenarios requiring secure fittings under pressure, flanges provide a robust solution for connecting pipes and machinery. Choosing the right combination of these steel pipe fittings will significantly impact the success of your construction project, making them essential considerations in your planning phase.

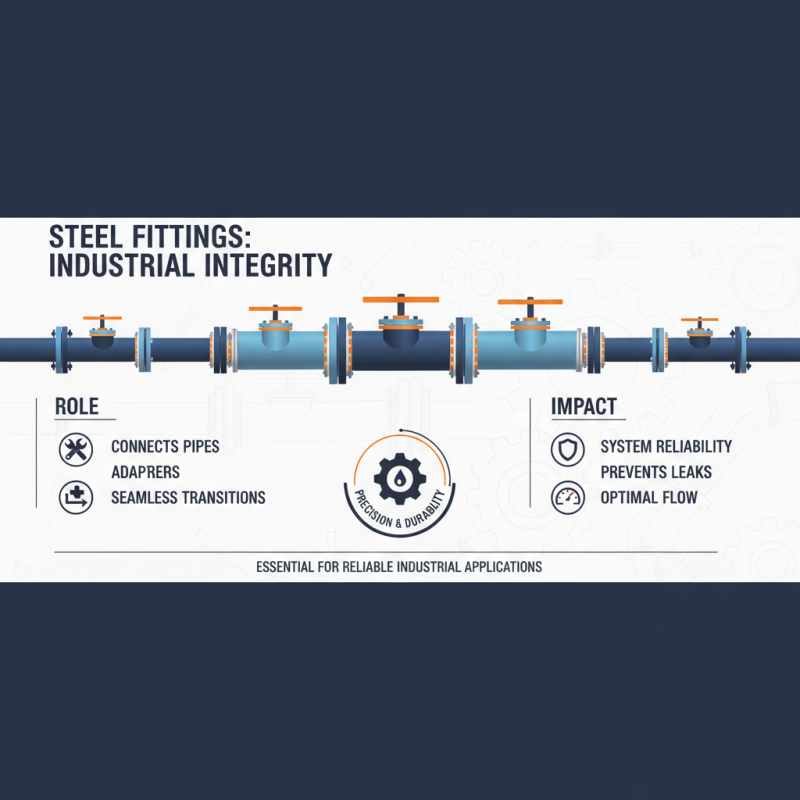

Steel fittings play a crucial role in the functionality and reliability of industrial applications. These components serve as essential connectors and adapters within piping systems, enabling the seamless transition between pipes of different sizes, shapes, and materials. In a world where precision and durability are paramount, the significance of steel fittings becomes evident as they ensure the integrity of the entire system, preventing leaks and maintaining optimal flow rates.

Moreover, the use of steel fittings in various industries, from construction to manufacturing, underscores their importance in maintaining safety and operational efficiency. Their ability to withstand high pressure and extreme temperatures makes them ideal for demanding environments. Additionally, the corrosion resistance of quality steel fittings contributes to the longevity of installations, reducing maintenance costs and minimizing downtime. By understanding the integral role of steel fittings, project managers and engineers can make informed decisions that enhance the overall performance of their piping systems.

When tackling construction projects, understanding the key specifications and standards for steel pipe fittings is crucial for ensuring safety and compliance. Steel pipe fittings are governed by various specifications, such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI). According to industry reports, adherence to these standards not only enhances the durability of fittings but also optimizes their performance under various environmental conditions. For example, ASTM A234 outlines the requirements for wrought carbon and alloy steel fittings, providing a benchmark for quality that contractors can rely on.

For optimal usage, it’s essential to prioritize the correct fitting materials based on the intended application. For instance, high-pressure applications often require fittings compliant with the ASME B16.25 standard, ensuring they can withstand significant stress without failure. Additionally, understanding the impact of industry certifications can guide selections; fittings bearing the appropriate certification symbols indicate that they meet specific performance criteria.

Tip: Always verify the specifications of the fittings with your project requirements before purchase to prevent costly delays. Additionally, factoring in environmental considerations—such as corrosion resistance and temperature tolerance—will lead to better decision-making regarding the types of steel pipe fittings to utilize. By emphasizing these specifications in your planning phase, you enhance the project's overall integrity and longevity.

When selecting steel pipe fittings for your project, durability and corrosion resistance are paramount. The choice of material grades plays a crucial role in ensuring the fittings can withstand the rigors of their intended environment. Commonly used grades such as ASTM A234 WPB provide a good balance of strength and resistance, making them suitable for general applications. For environments exposed to harsher conditions, high-performance grades like A420 or A860 can be employed, offering enhanced corrosion resistance and the ability to endure high-pressure situations.

Additionally, it’s essential to consider the coating and finish applied to the fittings. While the base material grade provides fundamental properties, coatings such as galvanization or epoxy can further enhance corrosion resistance. These protective layers are particularly vital in outdoor installations where moisture and varying temperatures can expedite corrosion processes. Ultimately, understanding the specific requirements of your project will guide you in selecting the appropriate material grades and coatings, ensuring longevity and reliability in your piping systems.

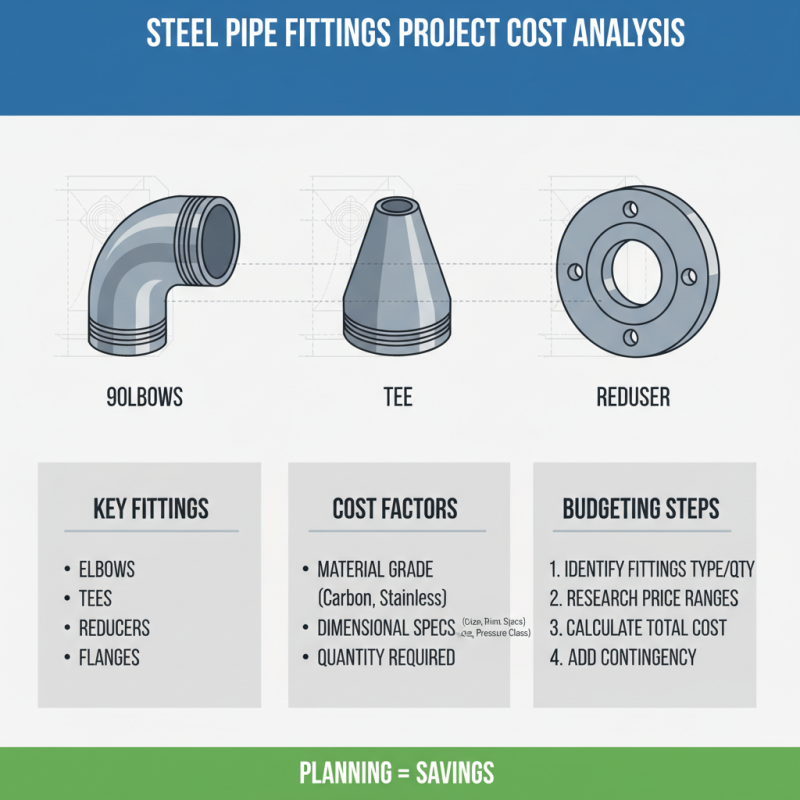

When planning for your next project involving steel pipe fittings, a thorough cost analysis is essential. Understanding the various fittings required, including elbows, tees, reducers, and flanges, will help in estimating the budget effectively. Each fitting comes with its own price range, influenced by factors such as material grade and dimensional specifications. Therefore, evaluating the quantity and type of fittings needed is a foundational step in your budgeting process.

Furthermore, considering the long-term durability and maintenance costs associated with different steel pipe fittings can lead to better financial decisions. While some fittings may come at a lower initial cost, they could incur higher maintenance expenses over time if they are not made from corrosion-resistant materials. By analyzing both upfront and lifecycle costs, project managers can allocate their budget more smartly, ensuring they select quality fittings that align with the project's overall goals and longevity requirements. This comprehensive approach to budgeting will ultimately contribute to the project's success and sustainability.